Industrial Cooling

-

Precise control of cooling processes

Processes with changes and fluctuations in the temperature of the delivery medium within short spaces of time

High operational safety and reliability

Higher temperatures and greater power outputs with ever smaller dimensions of devices and systems

Economical and sustainable concepts

High, reproducible quality of processes

-

Chillers/cooling machines

Cooling appliances

Cooling of welding devices, plasma cutters and similar devices

Cooling of industrial lasers

Cooling of medical lasers

-

Oils up to +180 °C

Water up to +140 °C

Water/glycol mixtures, fluorinated from -100 to +160 °C

De-mineralised water, cooling brine

Use in a circuit with direct cooling

Use in a primary circuit (secondary circuit) with indirect cooling

Open and closed circuits

-

Stable characteristic curve, even with changing operating states

High pressures and/or delivery pressures at relatively low flow rates

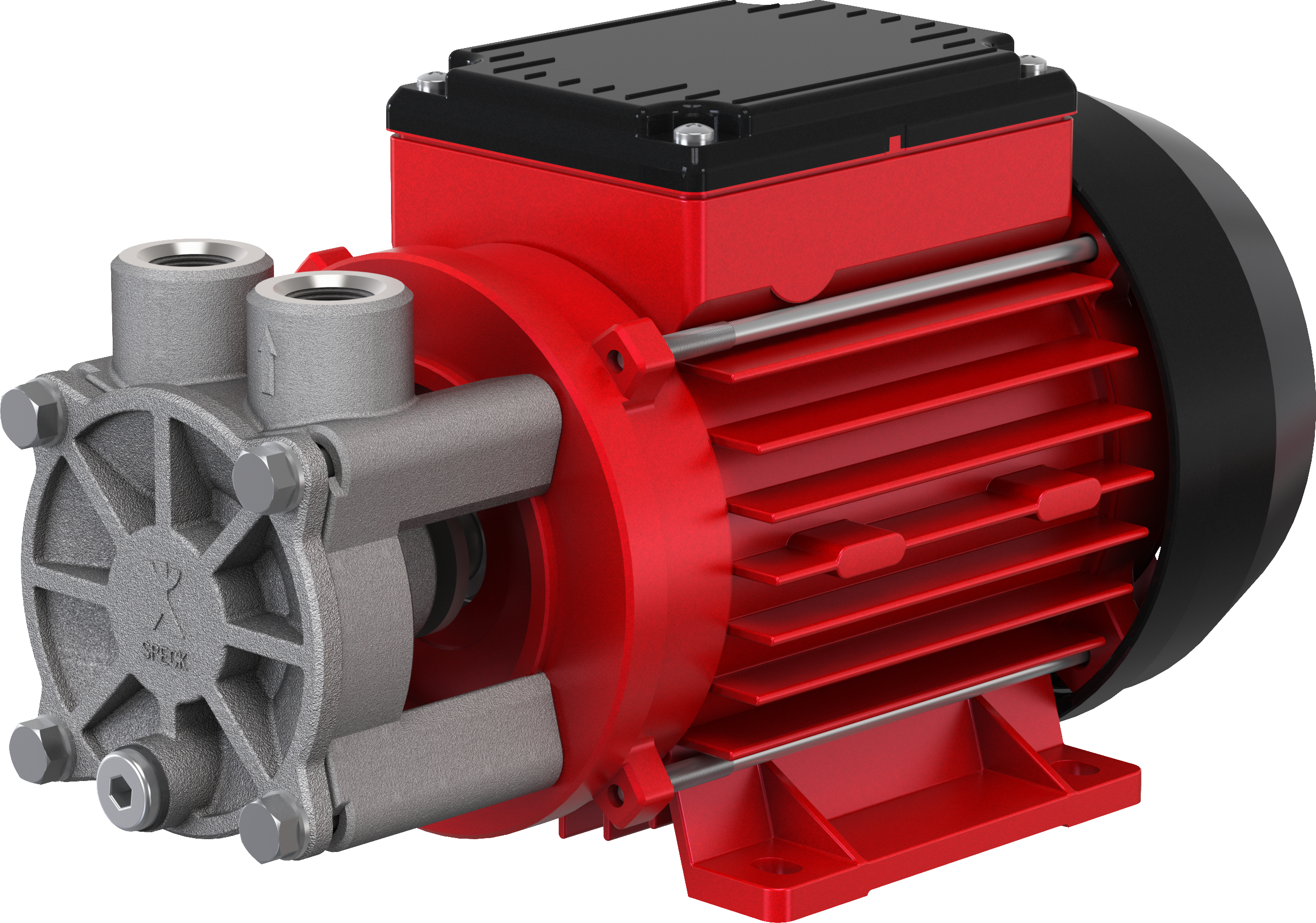

Pulsation-free delivery

Small dimensions thanks to close-coupled construction

Suitable for the delivery of gas shares

Safe in operation, reliable and suitable for continuous operation:

Maintenance-free pumps with sleeve bearings made from SiC

Mechanical seals which are tailored to the respective media or sealless vertical pumps

Tailored materials regarding conductivity, pH value or oxygen content of the media

Temperature Control

-

Precise control of thermal processes to within a tenth of a kelvin

Processes with changes and fluctuations in the temperature of the delivery medium within short spaces of time

High operational safety and reliability

Higher temperatures and greater power outputs with ever smaller tempering device dimensions

Economical and sustainable concepts

High, reproducible quality of processes

-

Laboratory tempering devices

Hot-water tempering devices

Oil tempering devices

-

Oils up to +400 °C

Hot water up to +220 °C

Mineral and synthetic thermal oils, silicon oils

Water/glycol mixtures, fluorinated from -100 to +160 °C

De-mineralised water, cooling brine

-

Stable characteristic curve, even with changing operating states

High pressures and/or delivery pressures at relatively low flow rates

Pulsation-free delivery

Suitable for leak-stop operation due to reversible delivery direction

Small dimensions thanks to close-coupled construction

Suitable for the delivery of gas shares

Safe in operation, reliable and suitable for continuous operation:

Maintenance-free magnetic couplings

Robust sleeve bearings made from SiC

Tailored materials regarding conductivity, pH value or oxygen content of the media

Heating & Cooling Technology

-

Controlling extremely high or extremely low temperatures

High requirements in terms of safety, health and environmental protection

Economical and sustainable concepts

High and reproducible quality of end products and processes

Adherence to legal specifications

-

Heating industrial processes, including ovens (or furnaces), calenders, boilers and large deep-fat fryers up to +400 °C

Cooling of industrial processes up to -100 °C

Tempering rollers, e.g. in mangle systems and the printing industry

-

Oils -100 to +350 °C

Hot water up to +180 °C

-

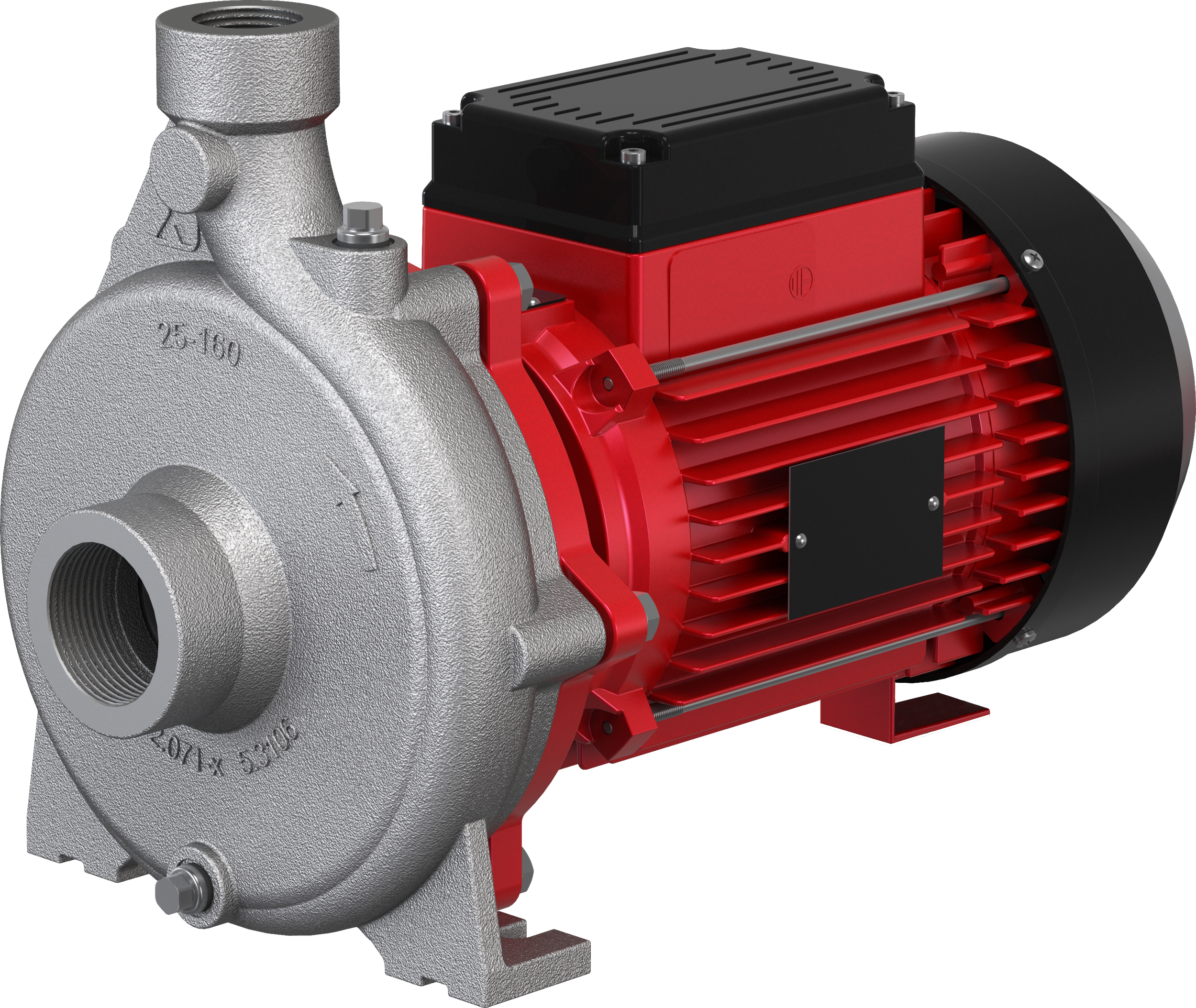

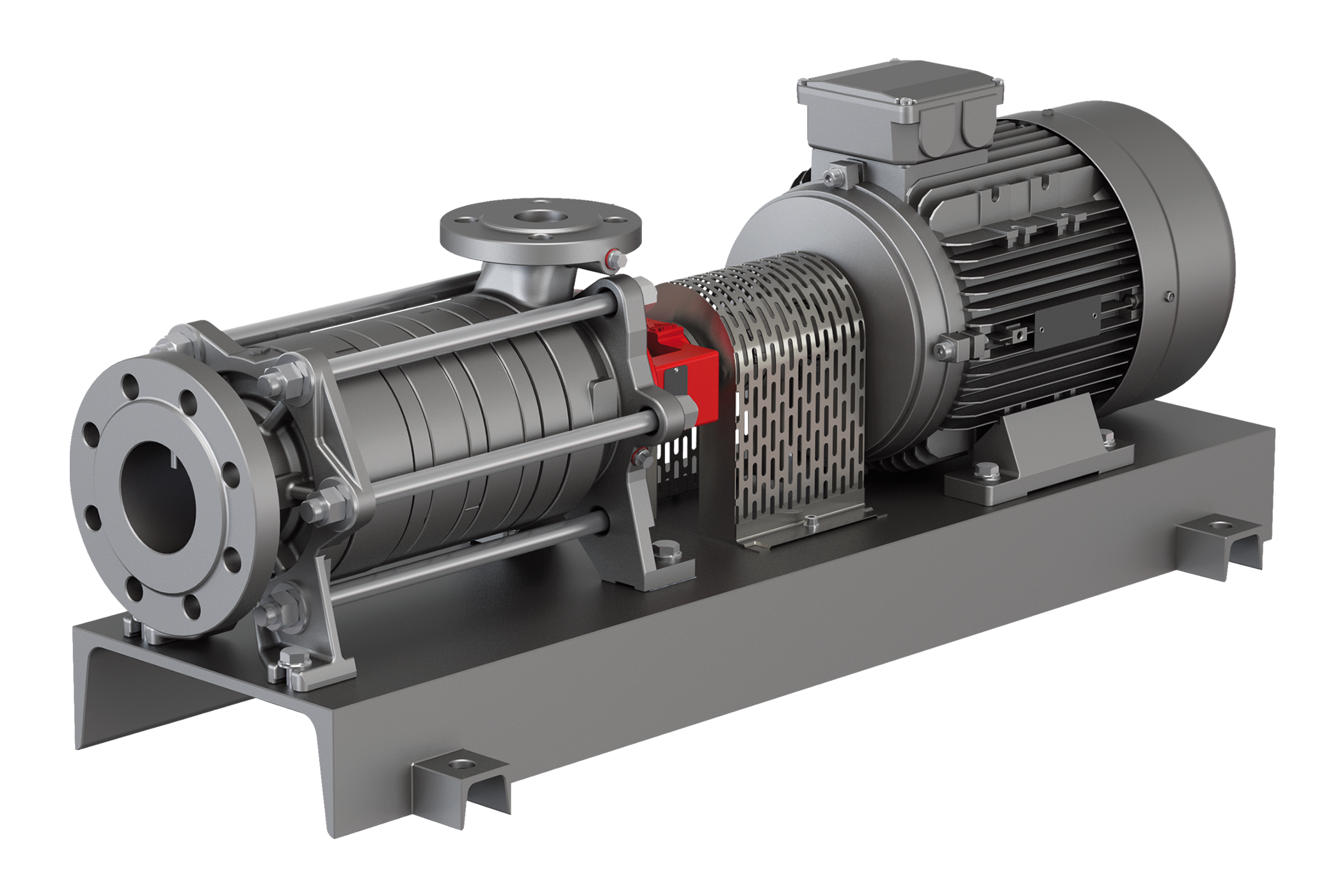

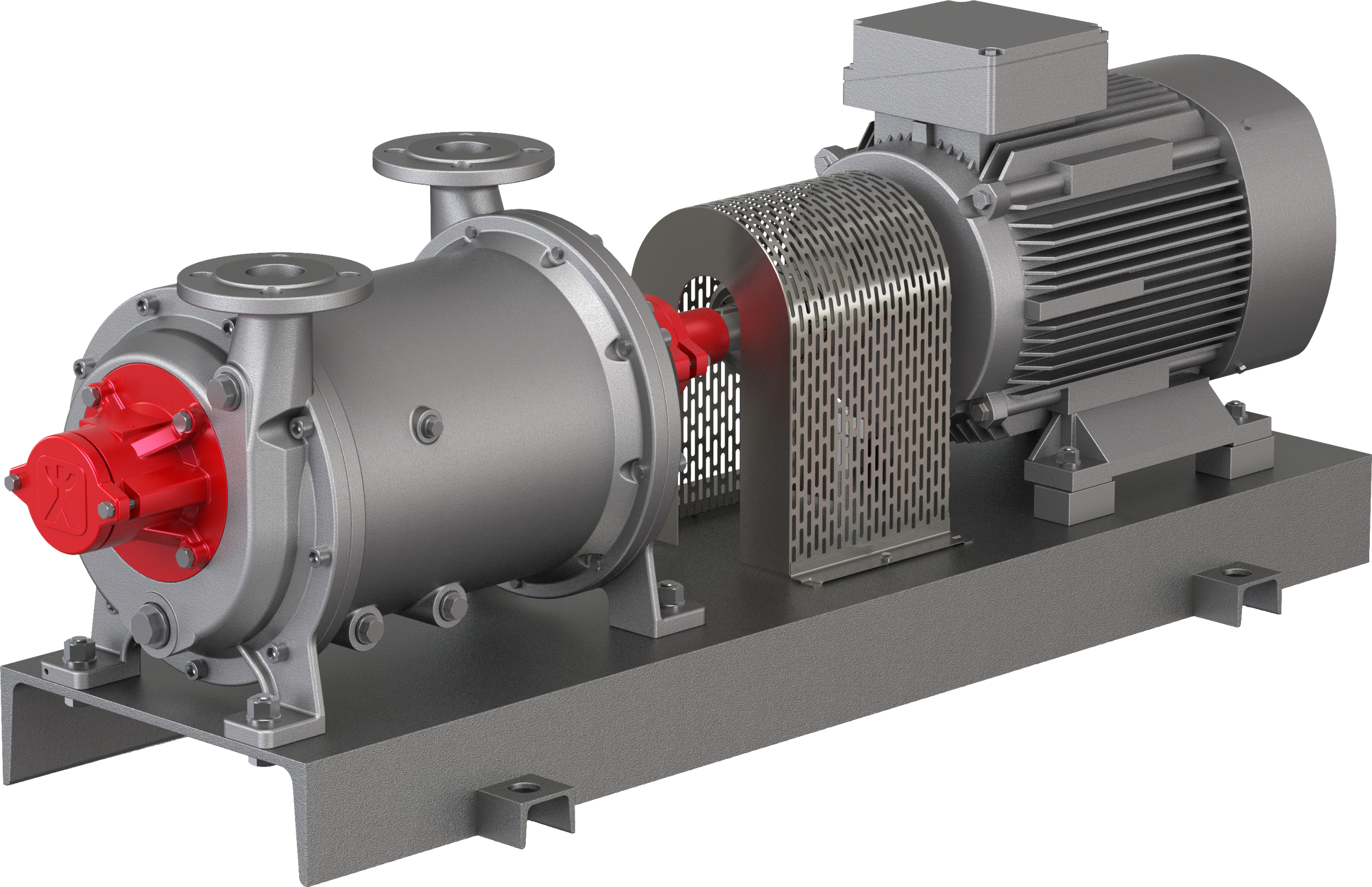

Centrifugal pumps in modular systems with standard sizes

Developed for heat transfer systems as per DIN 4754

Bearing bracket sizes 360 and 470, PN 16

Uncooled mechanical seals with dry-run safety function or magnetic coupling with start-up safety device

Robust bearings

For larger sizes: centreline casing mounting and casing with double volute

Smart and efficient dissipation of heat from bearings and seals

Suitable for continuous operation

Safe operation and reliable in the following areas of application

Thermal oil pumps

Mineral and synthetic thermal oils, silicon oils

Design in spheroidal graphite cast iron for temperatures from -40 to +350 °C (up to +400 °C upon request)

Design in stainless steel for temperatures from -100 to +250 °CHot water pumps with uncooled mechanical seals

Design in spheroidal graphite cast iron for temperatures up to +160 °C (+180 °C upon request)

Regenerative turbine pumpsHeat transfer pumps or thermal oil pumps from -40 to +350 °C

Hot water pumps up to +220 °C

Pressures up to 30 bar, higher pressures upon request

Side channel pumpsTemperatures from -100 to +350 °C

E.g. for delivering cooling brine or for filling and emptying thermal oil systems

Medical Engineering

-

Very high safety requirements and absolute reliability

High requirements in terms of market approvals and certifications

Customer- and application-specific developments

Suppliers with many years of proven ability to supply replacement parts or derivative products with the same technological compatibility

-

Sterilisation with devices ranging from small table-top sterilisers through to large clinical sterilisers

Sterilisation with laboratory and industrial autoclaves

Suction of saliva in dental surgeries

-

Gases and vapours up to +135 °C

Suction pressures up to 33 mbar abs. (5 mbar abs. with gas ejector)

Suction capacity from 2.5 to 1600 m³/h

Plastics industry

-

Energy saving and efficiency

High reliability and process security

High, reproducible quality of end products

Exchangeability or retrofitting in existing systems with restricted clearances

Noise minimisation

-

Wet and dry calibration of plastic profiles, particularly window frames, technical profiles and pipes

Extruder degasification and plastic recycling

Other vacuum processes in the plastics industry, e.g. manufacturing polystyrene parts

-

Gases, contaminated gases and gas/water mixtures

Suction pressures up to 33 mbar abs. (5 mbar abs. with gas ejector)

Suction capacity up to 1600 m³/h

Food & Beverage Industry

-

Safety, health and environmental protection

High requirements for hygiene and sterility with CIP-capable systems

Hygienic and gentle processing of end products

High, reproducible quality of end products

-

Filling bottles with beer, mixed beverages, mineral water and similar

Vacuum cutters

General processes such as degasification, extraction, suction and vacuum cooking

Curing systems

Delivery and circulation of

Beverages, milk and whey

Salt brine, curing brineMilk vending machines

Treatment of drinking water in osmosis plants

Rail & Road

-

High operational safety, reliability and long service life under difficult and changing ambient conditions such as

Exposure to shocks and rattling

Fluctuating outside temperatures and air humidity

Exposure to salt and spray

Many years of proven ability to supply replacement parts or derivative products with the same technological compatibility

-

Pre-heating of motors and air-conditioning in drivers' cabs and passenger compartments

Delivering drinking water and service water in carriages and buffet cars

Delivering windscreen washer fluid or fuel in locomotives

Cooling electrical and mechanical vehicle components such as traction coolers and gearboxes

-

Circulation in air conditioning systems (auxiliary heaters)

Circulation in fuel cell stack primary cooling circuits

Feeding in and discharging milk in milk tankers

Spraying separating agent (water) onto the drum surfaces of road rollers

Cooling of asphalt and concrete milling machines (including dust binding)

Dust binding in street sweeper machines

Cooling the high-performance gearboxes on tractors

Energy Technology

-

Economy and efficiency

Process reliability and operational safety

Comprehensive and detailed product documentation

Many years of proven ability to supply replacement parts or derivative products with the same technological compatibility

-

Delivery and circulation in closed circuits

Feeding boilers in boiler systems and steam generators

Tank systems, including delivering liquid gas

Delivery of diesel in backup generators in power stations

Process heating

-

Oils up to +350 °C

Water up to +220 °C

Hot water, liquid gas, fuels, vapours and condensates etc.

Chemical & Pharmaceutical Industry

-

Safety, health and environmental protection (e.g. ATEX, "TA Luft")

High requirements for hygiene and sterility with CIP-capable systems

Hygienic and gentle processing of end products

High and reproducible quality of end products and processes

Economical and sustainable concepts

-

Distilling and separation of liquids

Recovery of condensates, e.g. solvents

Drying of bulk solids, e.g. washing powder, fertiliser, salts, plastic granulates etc.

Extraction of liquids, e.g. palm oil

Delivering aggressive, highly flammable and toxic media

Systems with pressures up to 100 bar

Your OEM Application

-

Individual and specific solutions

Utmost reliability of the product in the application

Cost-optimisation

Long-term, trusting partnership in the development and maintenance of your products

Application-specific modes of operation

Regenerative turbine pumps, centrifugal pumps, side channel pumps, displacement pumps, liquid ring vacuum pumps and vacuum systems

Application-specific materials

Stainless steel, grey cast iron, non-ferrous metal, plastic, aluminium, sealing materials, special materials (e.g. Hastelloy® or seawater-resistant materials)

Country- and application-specific drive systems

Voltages, direct and alternating currents, IE3, IE4 etc.

Motor certifications: UL, CSA, CEL

With frequency converterSmallest possible installation spaces