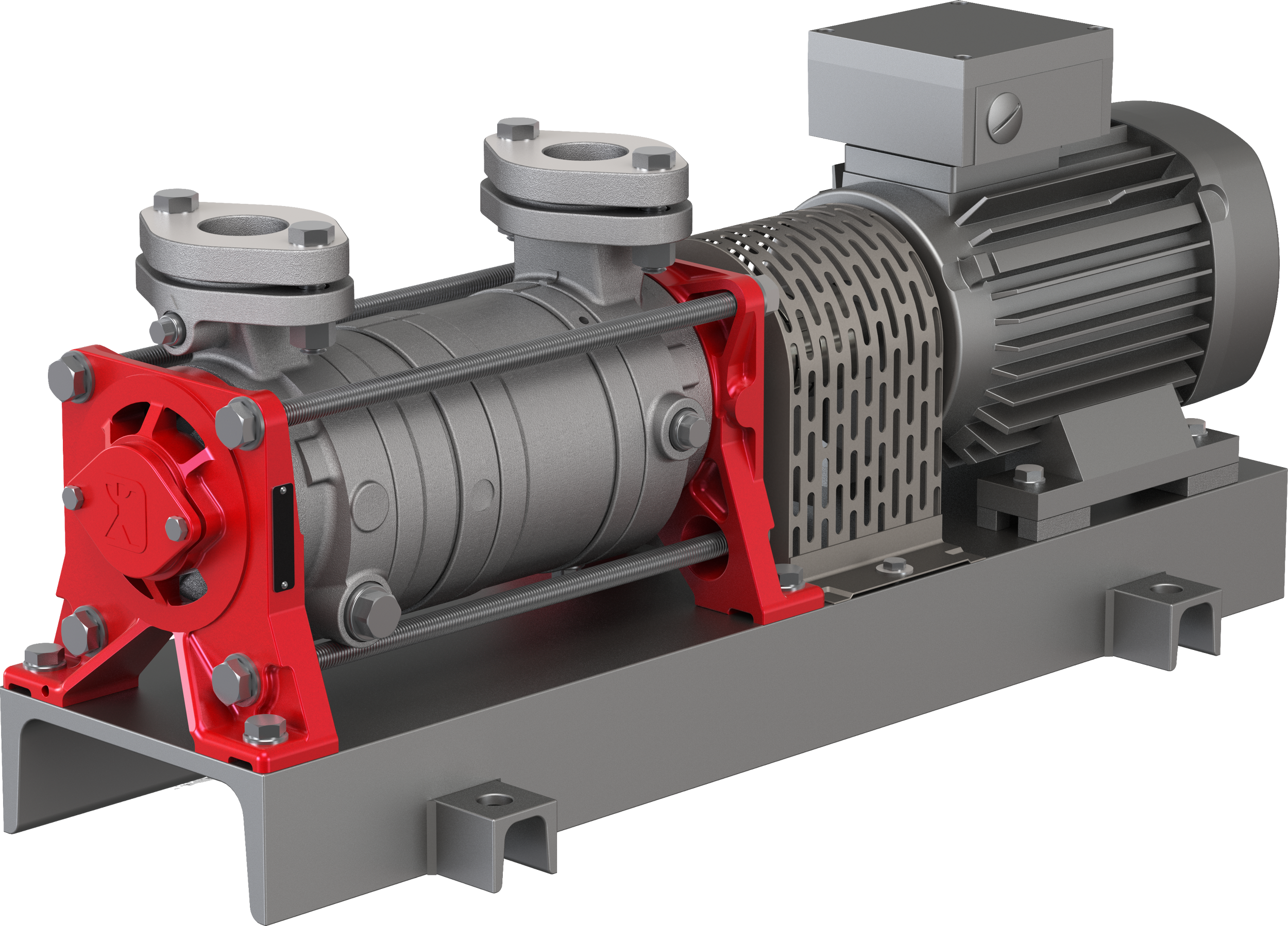

VH-Series

-

Liquid ring vacuum pump

Free-flying shaft

Single-acting mechanical seal,

dual-acting mechanical sealTwo-stage

Valveless

Specially selected materials and seals for application-specific designs

Oil-free vacuum generation

Use of condensed process medium as the operating liquid

Liquid carry over at a constant vacuum

-

Plastics processing

Manufacturing of PET

Food and beverage industry

Vacuum cutters

Aspiration

Medical technology

Steam sterilisation systems

Plastics processing

Extruder degasification

Polystyrene moulded parts processing

Drying of plastic granulate

Decontamination in PET recycling systems

Food and beverage industry

Beverage filling plants

Sous-vide cooking

Degasification

Extraction

Sterilisers

Reverse osmosis systems

Chemical and pharmaceutical industry

Filling plants for paste media

Distillation

Filtration

Evaporation

Degasification

Drying of loose bulk materials

Solvent recovery

Condensate drainage

-

Product type: Liquid ring vacuum pump

Stages: 2

Shaft sealing: Mechanical seal

Pump design: Free-flying shaft

Typical media: Dry and moist gases

Variable speed: Frequency (converter-compatible motor on request)

Suction pressure: ext.33–800 mbar

Suction capacity: 7.0–1589.0 m3/h

Motor current type: 1~/3~

Nominal motor power: 0.8 – 40 kW

Nominal motor speed:

975 rpm

1450 rpm

2800 rpmSuction-side connection design: Oval flange in acc. with DIN 2558 Flange in acc. with DIN EN 1092 and ANSI B 16.5

Suction-side connection size: G 1¼”

Pressure-side connection design: Oval flange in acc. with DIN 2558 Flange in acc. with DIN EN 1092 and ANSI B 16.5

Pressure-side connection size: G 1¼”

Material designs:

Grey cast iron

Stainless steel

Free of non-ferrous metalsExplosion protection:

None

II 3G, II 3D

II 2G, II 2D

II 2/2G

II 1/2G

II 1+H2/2G

-

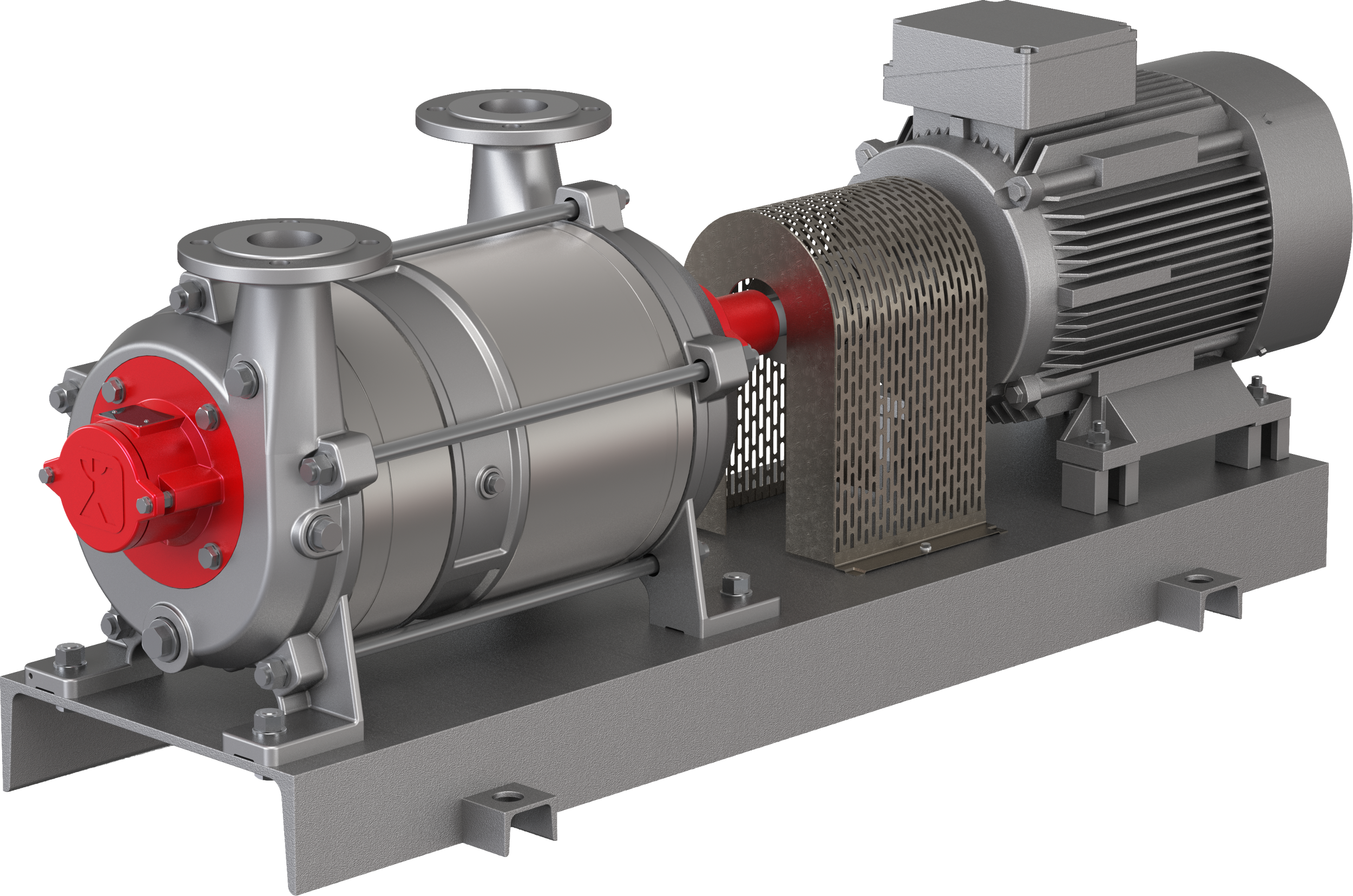

VHC-Series

-

Liquid ring vacuum pump

Free-flying shaft

Single-acting mechanical seal,

dual-acting mechanical seal,

magnetic couplingTwo-stage

Valveless

Specially selected materials and seals for application-specific designs

Oil-free vacuum generation

Use of condensed process medium as the operating liquid

Liquid carry over at a constant vacuum

-

Plastics processing

Manufacturing of PET

Food and beverage industry

Vacuum cutters

Aspiration

Medical technology

Steam sterilisation systems

Plastics processing

Extruder degasification

Polystyrene moulded parts processing

Drying of plastic granulate

Decontamination in PET recycling systems

Food and beverage industry

Beverage filling plants

Sous-vide cooking

Degasification

Extraction

Sterilisers

Reverse osmosis systems

Chemical and pharmaceutical industry

Filling plants for paste media

Distillation

Filtration

Evaporation

Degasification

Drying of loose bulk materials

Solvent recovery

Condensate drainage

-

Product type: Liquid ring vacuum pump

Stages: 2

Shaft sealing/coupling: Mechanical seal or magnetic coupling

Pump design: Free-flying shaft

Typical media: Dry and moist gases

Variable speed: Frequency (converter-compatible motor on request)

Suction pressure: ext.33–800 mbar

Suction capacity: 55.0–1589.0 m3/h

Motor current type: 3~

Nominal motor power: 2.9 – 39.2 kW

Nominal motor speed:

975 rpm

1450 rpmSuction-side connection design: Flange in acc. with DIN EN 1092 and ANSI B 16.5

Suction-side connection size: DN 40 – DN 100

Pressure-side connection design: Flange in acc. with DIN EN 1092 and ANSI B 16.5

Pressure-side connection size: DN 40 – DN 100

Material designs:

Grey cast iron

Stainless steel

Free of non-ferrous metalsExplosion protection:

None

II 3G, II 3D

II 2G, II 2D

II 2/2G

II 1/2G

II 1+H2/2G

-

VU0-Series

-

Liquid ring vacuum pump

Free-flying shaft

Single-acting mechanical seal,

dual-acting mechanical sealDeveloped for applications with operating points of over 200 mbar

Single-stage

Sizes 0020–0220 valveless,

sizes 300–1600 with valve flapsSpecially selected materials and seals for application-specific designs

Oil-free vacuum generation

Use of condensed process medium as the operating liquid

Liquid carry over at a constant vacuum

-

Chemical and pharmaceutical industry

Filtration

Food and beverage industry

Degasification

Plastics processing

Manufacturing of PET

Food and beverage industry

Extraction

Chemical and pharmaceutical industry

Condensate drainage

-

Product type: Liquid ring vacuum pump

Stages: 2

Shaft sealing: Mechanical seal

Pump design: Free-flying shaft

Typical media: Dry and moist gases

Variable speed: Frequency (converter-compatible motor on request)

Suction pressure ext:.120–800 mbar

Suction capacity: 8.0–1552.0 m3/h

Motor current type: 3~

Nominal motor power: 0.8 – 28.4 kW

Nominal motor speed:

975 rpm

1450 rpm

2800 rpmSuction-side connection design: Oval flange in acc. with DIN 2558 Flange in acc. with DIN EN 1092 and ANSI B 16.5

Suction-side connection size:

G 1¼”– DN 125Pressure-side connection design: Oval flange in acc. with DIN 2558 Flange in acc. with DIN EN 1092 and ANSI B 16.5

Pressure-side connection size:

G 1¼”– DN 125Material designs:

Stainless steel

Grey cast iron

Free of non-ferrous metalsExplosion protection:

None

II 3G, II 3D

II 2G, II 2D

II 2/2G

II 1/2G

II 1+H2/2G

-

VU1-Series

-

Liquid ring vacuum pump

Close-coupled pump, bracket pump or free-flying shaft

Single-acting mechanical seal,

dual-acting mechanical seal,

magnetic couplingTwo-stage

Valveless

Quiet-running

Specially selected materials and seals for application-specific designs

Oil-free vacuum generation

Use of condensed process medium as the operating liquid

Liquid carry over at a constant vacuum

-

Chemical and pharmaceutical industry

Filtration

Food and beverage industry

Degasification

Plastics processing

Manufacturing of PET

Medical technology

Steam sterilisation systems

Food and beverage industry

Sterilisers

Chemical and pharmaceutical industry

Distillation

Food and beverage industry

Vacuum cutters

Plastics processing

Extruder degasification

Drying of plastic granulate

Decontamination in PET recycling systems

Food and beverage industry

Beverage filling plants

Sous-vide cooking

Reverse osmosis systems

Chemical and pharmaceutical industry

Filling plants for paste media

-

Product type: Liquid ring vacuum pump

Stages: 2

Shaft sealing/coupling: Mechanical seal or magnetic coupling

Pump design:

Close-coupled pump

Bracket pump

Free-flying shaftTypical media: Dry and moist gases

Variable speed: Frequency converter-compatible motor on request

Suction pressure ext: .33–800 mbar

Suction capacity:

55.0–186.0 m3/hMotor current type: 3~

Type of motor: Asynchronous motor

Nominal motor power: 2.9 – 4.9 kW

Nominal motor speed:

1450 rpmSuction-side connection design: Flange in acc. with DIN EN 1092 and ANSI B 16.5

Suction-side connection size:

DN 40Pressure-side connection design: Flange in acc. with DIN EN 1092 and ANSI B 16.5

Pressure-side connection size:

DN 40Material designs:

Stainless steel

Grey cast iron

Free of non-ferrous metalsExplosion protection:

None

II 3G, II 3D

II 2G, II 2D

II 2/2G

II 1/2G

II 1+H2/2G

-

VZ-Series

-

Liquid ring vacuum pump

Free-flying shaft

Single-acting mechanical seal,

dual-acting mechanical sealSingle-stage

Valve flaps

Specially selected materials and seals for application-specific designs

Oil-free vacuum generation

Use of condensed process medium as the operating liquid

Liquid carry over at a constant vacuum

-

Chemical and pharmaceutical industry

Filtration

Food and beverage industry

Degasification

Plastics processing

Manufacturing of PET

Food and beverage industry

Extraction

Chemical and pharmaceutical industry

Condensate drainage

Food and beverage industry

Aspiration

Medical technology

Steam sterilisation systems

Food and beverage industry

Sterilisers

Chemical and pharmaceutical industry

Distillation

Evaporation

Degasification

Food and beverage industry

Vacuum cutters

Plastics processing

Extruder degasification

Polystyrene moulded parts processing

Drying of plastic granulate

Decontamination in PET recycling systems

Food and beverage industry

Beverage filling plants

Sous-vide cooking

Reverse osmosis systems

Chemical and pharmaceutical industry

Filling plants for paste media

Drying of loose bulk materials

Solvent recovery

-

Product type: Liquid ring vacuum pump

Stages: 2

Shaft sealing: Mechanical seal

Pump design: Free-flying shaft

Typical media: Dry and moist gases

Variable speed: Frequency (converter-compatible motor on request)

Suction pressure ext: .33–800 mbar

Suction capacity:

110.0–425.0 m3/hMotor current type: 3~

Nominal motor power: 7.2 – 10.4 kW

Nominal motor speed:

1450 rpmSuction-side connection design: Oval flange in acc. with DIN 2558 Flange in acc. with DIN EN 1092 and ANSI B 16.5

Suction-side connection size:

G 1¼”– DN 125Pressure-side connection design: Oval flange in acc. with DIN 2558 Flange in acc. with DIN EN 1092 and ANSI B 16.5

Pressure-side connection size:

G 1¼”– DN 125Material designs:

Stainless steel

Grey cast iron

Free of non-ferrous metalsExplosion protection:

None

II 3G, II 3D

II 2G, II 2D

II 2/2G

II 1/2G

II 1+H2/2G

-

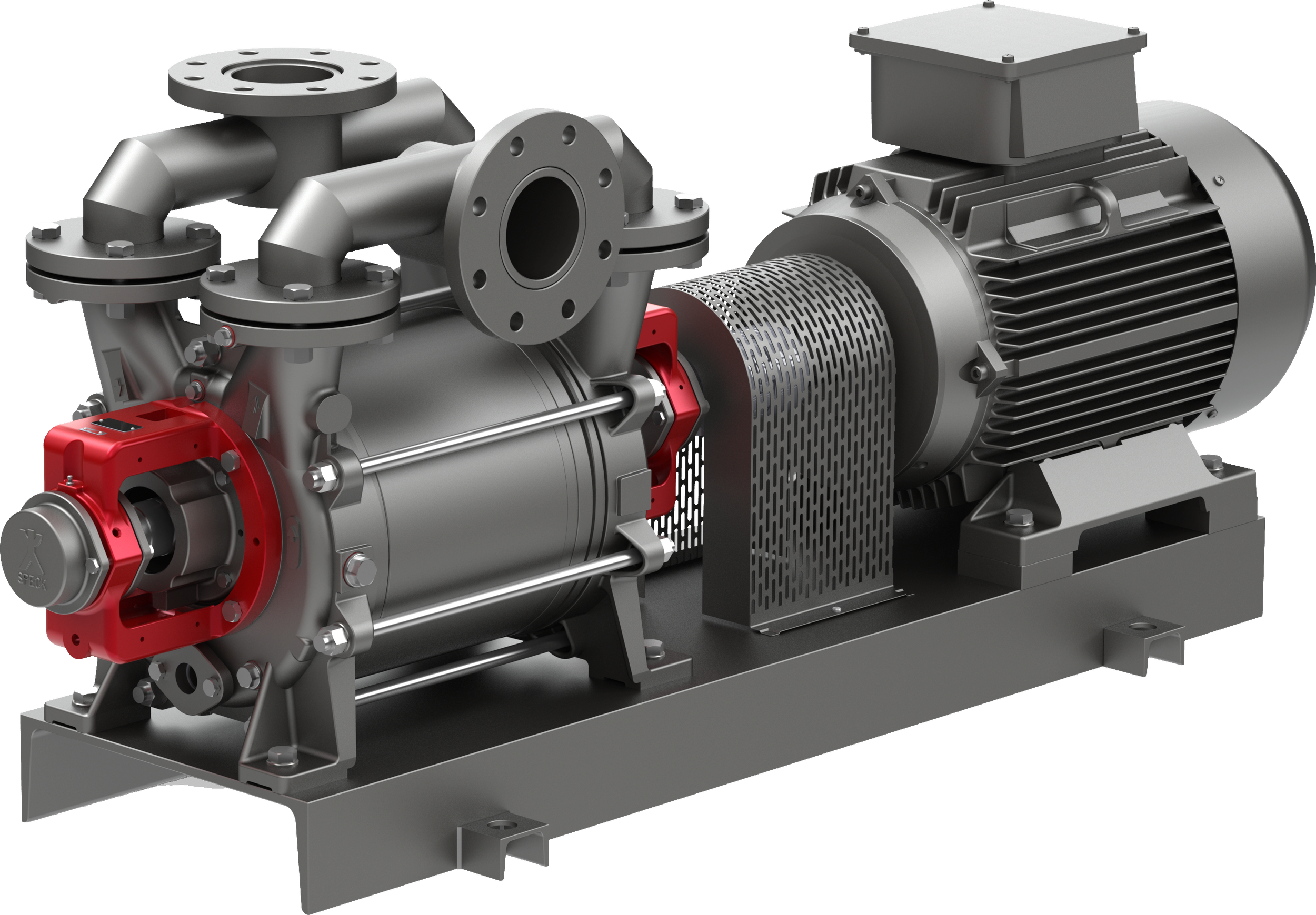

VHD-Series

-

Liquid ring vacuum pump

Free-flying shaft

Single-acting mechanical seal,

dual-acting mechanical seal,

magnetic couplingTwo-stage

Valveless

Low number of sealing surfaces thanks to one-piece stage casing

Pressure-resistant up to 10 bar

Specially selected materials and seals for application-specific designs

Oil-free vacuum generation

Use of condensed process medium as the operating liquid

Liquid carry over at a constant vacuum

-

Plastics processing

Manufacturing of PET

Food and beverage industry

Vacuum cutters

Aspiration

Medical technology

Steam sterilisation systems

Plastics processing

Extruder degasification

Polystyrene moulded parts processing

Drying of plastic granulate

Decontamination in PET recycling systems

Food and beverage industry

Beverage filling plants

Sous-vide cooking

Degasification

Extraction

Sterilisers

Reverse osmosis systems

Chemical and pharmaceutical industry

Filling plants for paste media

Distillation

Filtration

Evaporation

Degasification

Drying of loose bulk materials

Solvent recovery

Condensate drainage

-

Product type: Liquid ring vacuum pump

Stages: 2

Shaft sealing/coupling: Mechanical seal or magnetic coupling

Pump design: Free-flying shaft

Typical media: Dry and moist gases

Variable speed: Frequency (converter-compatible motor on request)

Suction pressure ext: .33–800 mbar

Suction capacity: 150.0–620.0 m3/h

Motor current type: 3~

Nominal motor power: 7.3 – 17.6 kW

Nominal motor speed: 1450 rpm

Suction-side connection design: Flange in acc. with DIN EN 1092 and ANSI B 16.5

Suction-side connection size:

DN 40 – DN 65Pressure-side connection design: Flange in acc. with DIN EN 1092 and ANSI B 16.5

Pressure-side connection size:

DN 40 – DN 65Material designs:

Grey cast iron

Stainless steel

Free of non-ferrous metalsExplosion protection:

None

II 3G, II 3D

II 2G, II 2D

II 2/2G

II 1/2G

II 1+H2/2G

-

Brochure datasheet - VHD Series